|

As a relatively new industry, LNG has grown to be one of the major industries concerning the use of valves. There are many valve manufacturers producing cryogenic valves and I often read about new products being introduced specifically for use in the LNG industry, for example the three specialized products Pentair presented at the World Gas Conference in Paris earlier this month.

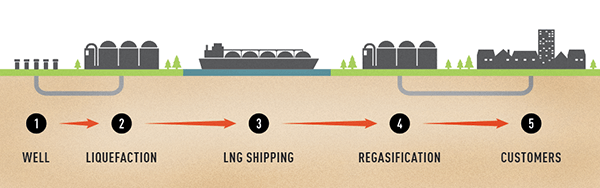

LNG, or liquefied natural gas, is natural gas that is cooled to -260° Fahrenheit (-162°C) until it becomes a liquid. Then it is stored at essentially atmospheric pressure. Converting natural gas to LNG, reduces its volume by about 600 times, allowing it to be transported internationally. Once delivered to its destination, the LNG is warmed back into its original gaseous state so that it can be used just like existing natural gas supplies, by sending it through pipelines to its customers. LNG is used across the residential, commercial and industrial sectors for purposes as diverse as heating and cooling homes, cooking, generating electricity and manufacturing paper, metal, glass, and other materials. LNG is also increasingly being used to fuel heavy-duty vehicles. You can imagine that this process requires a lot of valves.

Liquefactation of LNG. Source: APPEA

The liquefaction of natural gas dates back to the 19th century, when British chemist and physicist Michael Faraday, among others, experimented with liquefying different types of gases, including natural gas. Liquefying natural gas made it possible to transport the fuel and in January 1959, the world’s first LNG tanker carried liquefied natural gas from the US to the UK. This voyage demonstrated that large quantities of liquefied natural gas could be transported safely across the ocean.

In 1964, the British Gas Council began importing liquefied natural gas from Algeria, making the UK the world's first LNG importer and Algeria its first exporter. After the concept was shown to work in the UK, additional marine LNG liquefaction plants and import terminals were built in both the Atlantic and Pacific regions. The first exports of liquefied natural gas from the United States to Asia occurred in 1969. The LNG market in Europe and Asia continued to grow rapidly from that point on.

Because LNG is cooled to such low temperatures, valves used in the LNG industry must be specified to meet cryogenic temperatures of -168°C to -198°C. The development, transportation, and receiving of LNG requires valves and with the market for LNG expanding, the challenge of many valve manufacturers is to expand their product ranges to offer valves that are constructed of quality cast and forged materials. The performance and reliability of the valves are vital to the whole process, and this can only be achieved through critical design, manufacturing, and material selection. However, besides API 598 cryogenic valves have to meet BS 6364, which is tested with helium at -270°F (-168°C) to -325°F (198°C). A major challenge for current valve manufacturers is to not only remain competitive in this relatively new and growing market, but also maintaining and improving quality and performance. |